When you are seating a drum head, people will suggest pressing down with the palm of you hand in the middle of the head to “seat it” on the bearing edge.

DON’T DO THAT!

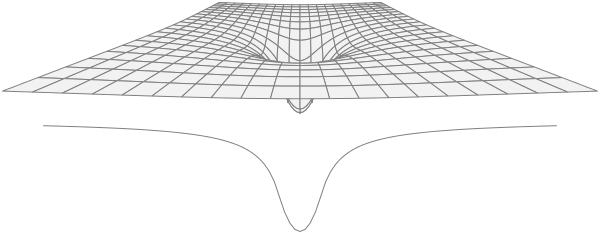

The drum head will deform most where the pressure is greatest. This means that the material in the middle of the drum head, i.e. under the palm of you hand, will stretch the most. This creates a saggy area or “soft spot” in the centre of your drum head while the material at the edge, which is where you want the drum head to stretch to the shape of the drum, will stretch the least.

The better method is to place the new head on the drum then over-tighten it using the tuning rods to seat it properly.

- After tightening each rod to finger tight then, working in a star pattern on opposite tuning rods, give each rod a quarter turn until they have all been tightened by at least one and a half turns. Stop if you feel that the head is reaching its limit.

- This method will stretch the drum skin over the bearing edge of the drum causing it to deform to the shape of the bearing edge to give you a better contact between the drum skin and the shell of the drum.

- Then, again working in a star pattern, loosen each tuning rod by giving it a quarter turn anticlockwise until the rods are just finger tight.

- You can then start to tune your drum in the normal way.

TOP TIPS: Even on the most expensive drums, the bearing edge (this is the top edge which the drum skin touches the drum) will have minor imperfections. Over time the drum skin will shape itself to match these imperfections to give you the best contact between the drum and the skin.

If you ever need to remove the head from the drum then before you do make a note of its position so that you can put it back in the same spot. The best way to do this is to note down where the drum head logo is in relation to the maker’s logo on the drum. In the picture (below) the logo on the head is 36 degrees anticlockwise (or one tuning lug over) from the logo on the drum.

The same principle applies to wooden hoops, triple flanged hoops and (to a lesser extent) die-cast hoops which will also deform over time to match the shape of the drum head and your preferred tuning setup. When you remove a drum hoop then these should also be put back in the same position they were removed from.

The best way to do this is to put a piece of tape on the hoop where the drum maker’s logo is. Then when you replace the hoop you can line up the tape with the logo before you begin to tighten the hoop down.